Servo motors are indispensable components in robotics and mechatronics projects due to their precise control and reliability. To simplify motor integration, the L293D Motor Shield is a versatile and efficient tool for interfacing with various motors. This tutorial will guide you through the process of controlling a Hobby Servo Motor using an L293D Motor Shield and Arduino, covering connections, programming, and practical implementation.

Understanding the Components

Servo Motor

A standard servo motor consists of three pins:

- Ground (GND)

- Power Supply (+5V)

- Signal Pin – Used for controlling the motor’s angle.

Servo motors are popular for their ability to rotate precisely within a range of 0 to 180 degrees, making them ideal for applications like robotic arms, RC cars, and gimbals.

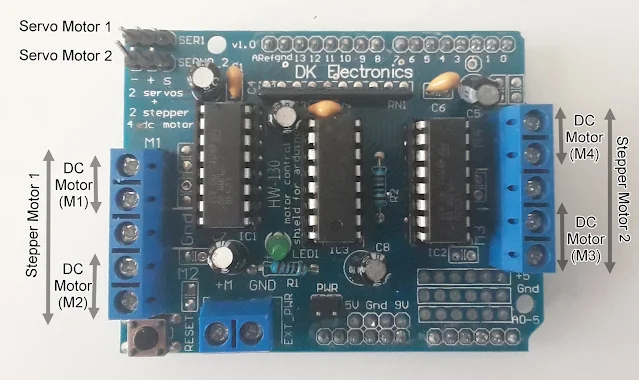

L293D Motor Shield

The L293D Motor Shield is an add-on board for Arduino that facilitates the control of motors.

It includes dedicated ports for Servo Motor 1 and Servo Motor 2, which correspond to pins 9 and 10 on the Arduino UNO. It also provides:

- Power supply pins (Vcc and GND)

- Signal connections for servo control

By mounting the shield onto the Arduino UNO, these connections are established automatically, streamlining your project’s setup.

Interfacing the Servo Motor with the L293D Motor Shield

Hardware Setup

- Connect the servo motor’s GND, Vcc, and Signal Pin to the Servo Motor 1 or Servo Motor 2 port on the L293D shield.

- Securely attach the motor shield to the Arduino UNO to link the servo signal pins to their designated Arduino pins.

Programming Arduino for Servo Motor Control

Arduino’s built-in Servo library makes it easy to control servo motors without requiring additional motor libraries like Adafruit Motor Shield.

Key Functions in the Servo Library

The Servo library provides methods to initialize and control servo motors effectively:

1. Attach the Servo Object

Servo myservo;

myservo.attach(9); // Connects the servo to pin 9

This method also supports optional parameters to define the pulse width range (default: 544–2400 µs).

2. Detach the Servo Object

myservo.detach();

This releases the PWM pin for other uses.

3. Control Servo Position

- By Angle:

myservo.write(90); // Moves servo to 90 degrees - By Microseconds:

myservo.writeMicroseconds(1500); // Midpoint position

4. Read Servo Position

int currentAngle = myservo.read();

Example Code

The following program rotates the servo motor from 0 to 180 degrees and then back to 0 degrees in smooth increments:

#include <Servo.h>

Servo myservo; // create a servo object to control a servo

const int servoPin = 10;

int pos = 0; // variable to store the servo position

void setup(){

// attach the servo on pin 10 to the servo object

myservo.attach(servoPin);

}

void loop(){

// sweep from 0 degrees to 180 degrees

for(pos = 0; pos <= 180; pos += 1){

myservo.write(pos);

delay(15);

}

// sweep from 180 degrees to 0 degrees

for(pos = 180; pos >= 0; pos -= 1){

myservo.write(pos);

delay(15);

}

}

How It Works

Setup Phase:

The Servo object is created and attached to a specific pin on the Arduino.Loop Phase:

- The motor is instructed to move in a sweeping motion between 0° and 180°.

- Delays ensure smooth transitions between positions.

Control Flexibility:

By modifying the code, you can adjust the speed, range, and functionality of the servo motor.

Video Demonstration

Below is a demonstration of how to control a Hobby Servo Motor using the L293D Motor Shield and Arduino. Watch to understand the practical application of the steps explained above.

Conclusion

In this tutorial, we demonstrated how to interface and control a Hobby Servo Motor using the L293D Motor Shield and Arduino. The combination of the shield and the Servo library provides a user-friendly way to implement motor control in your projects.

Whether you are working on a robotic arm, an RC car, or any project requiring precise motor control, this setup is a versatile and reliable solution.

Further Reading

By mastering the use of motor shields and servo motors, you can take your robotics and mechatronics projects to the next level!